Moisture

When arranging delivery of your solid wood flooring, please ensure your house/space is as close to ‘lived-in’ conditions as possible. The subfloor and walls must be completely dry when laying solid wood flooring, and the rooms should be warm and well-ventilated. To help you prepare, Coppice & Crown will send through a handy checklist before delivery. Please refer to Table X for the accurate moisture readings required.

Humidity

At Coppice & Crown, we acclimatise your solid wood flooring to typical living conditions, ready for laying on arrival. However, if your property has high humidity levels, it can damage your natural wood flooring as each board will expand as it absorbs increased moisture from the air. If there’s no room for the wood flooring to expand, it can cause peaking – where the boards push upwards and create bounce.

If you are in the throes of a new build or renovation project, please carefully consider and plan the time required for the drying phase to prevent project delays and flooring damage. Make realistic timetables during the planning stage, plan the dehumidification process and use the correct type of concrete to avoid high humidity levels and excess moisture.

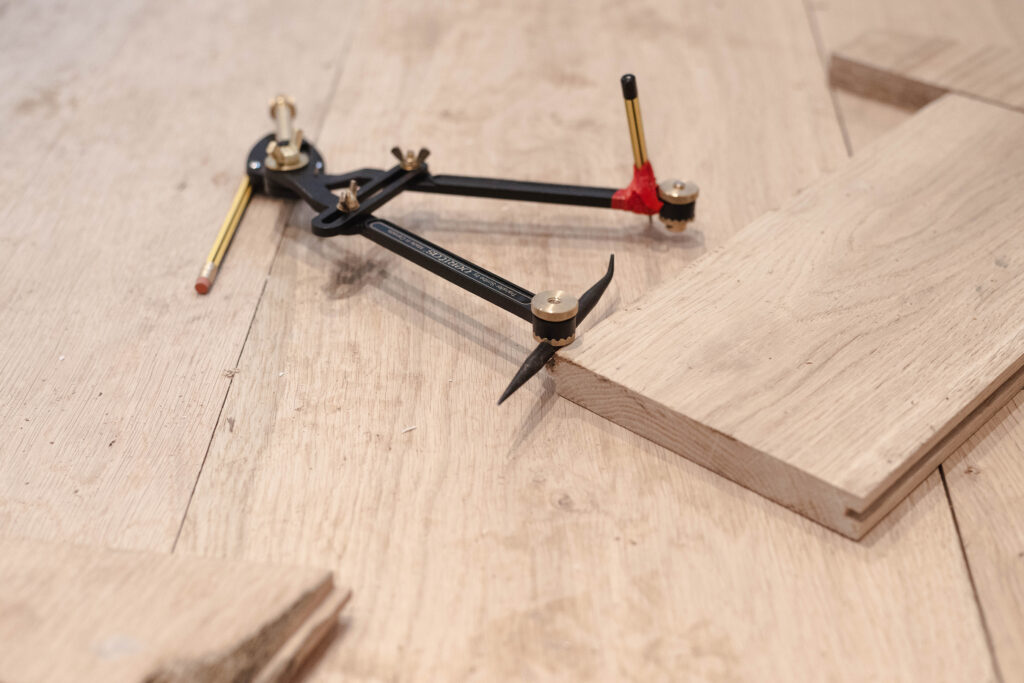

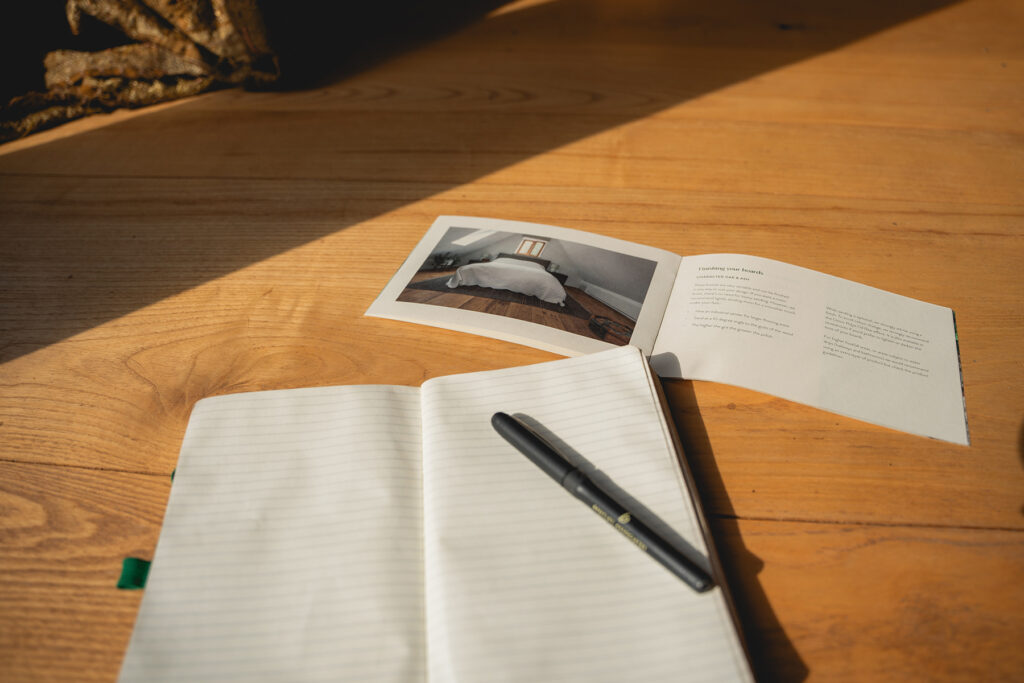

Equipment, Tools and Products you’ll need

We like to think laying our Ash, Chestnut, and Oak wood flooring is relatively simple. However, depending on your preferred finish, you may wish to employ a carpenter or floor fitter to carry out the work for you. We’re always happy to recommend wood flooring fitters in your area.

Like any building project, you’ll need specific tools and products to complete the work, including your chosen fixing and finish, ready to apply once you’ve sanded the boards. Again, we can advise you on the best solid wood flooring finish to achieve your desired look.

Day of Arrival: Board Numbers & Stacking

Delivery day is always exciting, but there are a few things you can do to ensure it goes smoothly. First, make sure you have one person per 10 sqm to help unload the boards at your end. If you have chosen our mixed-width flooring, we recommend stacking the boards in the colour of their widths, close to where they will be laid. It’ll make the job of installing your hardwood flooring much easier later.

Please do not stack your beautiful wooden floorboards outside, in a garage or shed.

The boards will arrive with blue numbers on the top, which you can easily sand out. These numbers appear on the face side of the board, tell you each board’s square foot, and correspond with the tally sheet sent across with your order. This sheet tells you the dimensions of the boards supplied. It’s not necessary for installation, but it is a useful record.

When handling your planks, always lift them; never pull or drag them sideways over the edge of the plank below. This will prevent you from pulling splinters off the edges or weakening them, causing them to splinter later.